HIGH PERFORMANCE, LOW INVESTMENT – THE NEW EASYSCAN SMART SCANNER

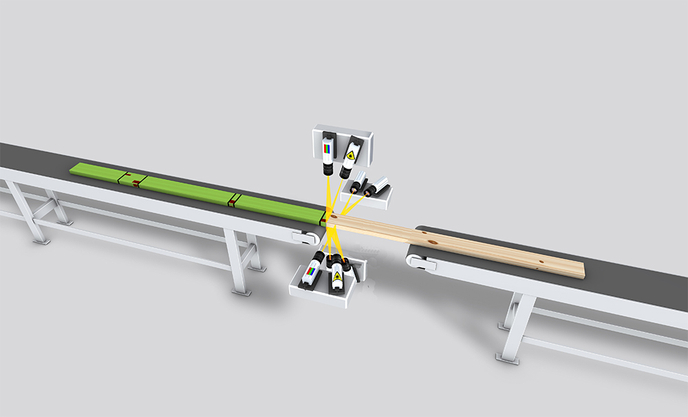

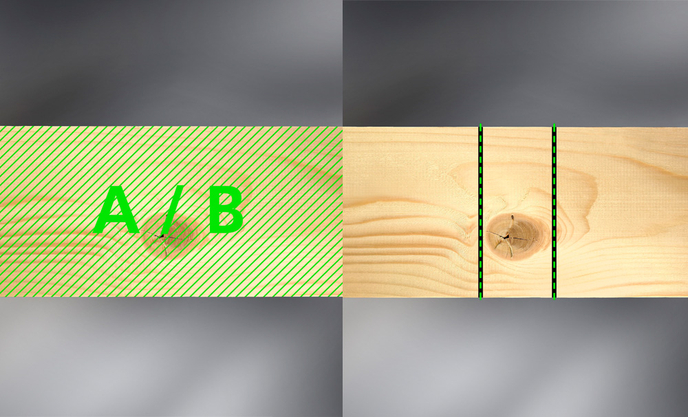

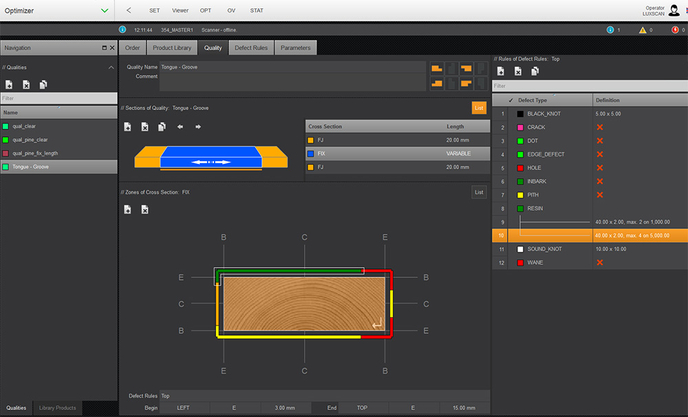

In modern wood processing, simple and fully automatic optimization is the key to efficient and high-performance production. An upstream scanner is an integral component of the overall line. The EasyScan Smart detects the relevant timber defects (knots, wane, holes etc.) on all sides in the blink of an eye on softwood as well as hardwood and supplies this data to one or two cross-cut saws downstream at full production speed.

Together with the OptiCore software, the EasyScan Smart not only brings your production completely new optimization possibilities, but also offers the maximum production control and transparency of your manufacturing process at an affordable cost. Thanks to a small footprint, it is the perfect solution for upgrading existing lines, but also a useful addition in new optimizing lines. From small entry-level production to large manufacturing facilities - the EasyScan Smart is a reliable partner.

The new EasyScan Smart has been designed for two applications: cross-cutting (Easyscan Smart C) and

sorting (Easyscan Smart S). Expect to profit from these new features in particular:

Find your variation suitable for your needs.

Download BrochureComparison EasyScan Smart C and Smart S

|

|

|

|||||

Comparison EasyScan Smart C and Smart S |

EasyScan Smart C (cross-cutting) | EasyScan Smart S (sorting) | |||||

| EasyScan Smart | C | S | |||||

| Max. speed (m/min) | up to 240 | up to 580 | |||||

| Max. boards (1/min) | up to 40 | up to 80 | |||||

| Max. throughput linear (1/min) | up to 140 | up to 280 | |||||

| Min. / Max. input length (mm) | 900 – 6500 | 900 – 6500 | |||||

| Min. / Max. input width (mm) | 35 – 260 | 35 – 260 | |||||

| Min. / Max. input thickness (mm) | 15 – 120 | 15 – 120 | |||||

| Hardwood / Softwood |

|

|

|||||

| Working height (mm) | 920 | 920 | |||||